In an Electric Car Future, Lithium Will Be King

For many years, few metals drew bigger yawns from mining executives than lithium, a lightweight element long associated mostly with moodstabilizing drugs.

Suddenly, the yawns are being replaced by eurekas. As awareness spreads that lithium is a crucial ingredient for hybrid and electric cars, a global hunt is under way for new supplies of the metal.

Toyota Tsusho, the material supplier for the big Japanese automaker, announced a joint venture in January with the Australian miner Orocobre to develop a $100 million lithium project in Argentina. That deal came only days after Magna International, the Canadian car parts company that is helping develop a battery-powered version of the Ford Focus, announced that it was investing $10 million in a small Canadian lithium firm that also has projects in Argentina.

They were the latest in a series of deals and projects announced over the last year, reflecting a new urgency among companies to assure themselves future supplies of the metal.

“There is a sea change under way,” James D. Calaway, the chairman of Orocobre, said. “We are at the front end potentially of a very significant increase in the demand for lithium for the emerging electric transportation sector.”

Mr. Calaway added, however, that the timing of any increase in lithium supply and demand was difficult to predict in large part because electric cars had yet to take off in any big way.

About 60 mining companies have begun feasibility studies in Argentina, Serbia and Nevada that could lead to more than $1 billion in new lithium projects in the next several years, while dozens of smaller projects are being proposed in China, Finland, Mexico and Canada.

The companies are competing for construction financing, and the future of most of the projects will depend on how popular electric cars eventually become. That is an open question since batteries remain expensive, recharging stations need to be developed, and consumer taste for cars that depend on regular stops at electric outlets remains untested.

“It’s moving so fast,” said Edward R. Anderson, president of TRU Group, a consultancy firm that specializes in the lithium industry. “There are a lot of people throwing money into this, and a lot of people are going to lose their money.”

In the meantime the four biggest current producers, which mine and otherwise gather lithium in Chile, Argentina and Australia, say they are planning to expand long-running projects as future demand warrants.

6In Bolivia, which has almost half of the world’s reserves, the leftist government is building a pilot production plant and is drilling exploratory holes. That Bolivia is a remote, unstable country often hostile to foreign investment has helped spur interest in producing lithium in neighboring Argentina and Chile, in Australia and in the United States. Several Canadian and American companies are making claims about future production prospects in Nevada, though few analysts foresee large-scale production from that state.

While most experts are skeptical that meaningful amounts of lithium can be produced domestically, they maintain that adequate supplies will be available from sources outside of Bolivia for many years to come and note that the biggest producer, Chile, is a dependable American ally.

Most of the lithium market serves a variety of industrial applications. About a quarter of all lithium produced is used for energy storage, in everything from cellphones to laptop computers to digital cameras.

That proportion stands to increase sharply if battery-powered cars take off. Lithium-ion batteries are the favored battery type for electric and hybrid vehicles because they carry more energy with less weight than other materials and because they lose their charge more slowly. They store about three times as much as energy per pound as a nickel-metal hydride battery.

Lithium is found in trace amounts in many places, but it is being produced commercially mainly by two methods. One is through mining and processing, a relatively expensive method that produces the metal mostly for glass, ceramics and the manufacturing of television tubes.

The more economical and significant method is through evaporation of lithium-containing brines, mostly in salt flats in the highland areas in South America and western China.

Lithium reservoirs have been formed over millions of years in highland bowls, after rivers and hot springs washed over rocks and leached the mineral from them. Producers drill wells into the salt flats and pump the brine into evaporation ponds. With the removal of water, the lithium content in the brine increases to a level where it can be collected and shipped to a chemical plant for processing.

By the standards of traditional gold and copper booms, the increase in interest in lithium is still muted among big mining companies. But with several major auto companies promising to market electric cars around the world over the next few years, demand may be poised to increase.

“We believe that demand is slated to rise dramatically,” according to a recent report by the investment adviser Byron Capital Markets.

스마터리빙

more [ 건강]

[ 건강]이제 혈관 건강도 챙기자!

[현대해운]우리 눈에 보이지 않기 때문에 혈관 건강을 챙기는 것은 결코 쉽지 않은데요. 여러분은 혈관 건강을 유지하기 위해 어떤 노력을 하시나요?

[ 건강]

[ 건강]내 몸이 건강해지는 과일궁합

[ 라이프]

[ 라이프]벌레야 물럿거라! 천연 해충제 만들기

[ 건강]

[ 건강]혈압 낮추는데 좋은 식품

[현대해운]혈관 건강은 주로 노화가 진행되면서 지켜야 할 문제라고 인식되어 왔습니다. 최근 생활 패턴과 식생활의 변화로 혈관의 노화 진행이 빨라지고

사람·사람들

more많이 본 기사

- 새해 첫날 대형화재 참사… 155명 … 1

- 해외 송금시 1% 세금 1월1일부터 부과 개시

- 또 일가족 살해·자살 4명 시신 발견 ‘비극’

- 한인 마켓에서 사라진 ‘플라스틱 봉투’

- ‘김태희♥’ 비, 난리통 연예계 속 의미심장 일침.. “나태하면 사건·사고 나”

- ‘255만 7,047명’ 미국내 한인… 1

- “키스, 불륜 맞지만 숙행은 억울해”..상간남 입 열었다

- 오바마케어 보조금 확대 결국 종료… 새해 최대 쟁점으로

- 새해초 폭우 강타… 엔젤레스 산악도로 붕괴

- “새해 복 많이 받으세요!” 2026 ‘병오년’ 힘찬 출발

- 시니어 ‘최소인출’ 미준수… 세금 불이익

- 뉴욕시 첫 무슬림 시장 맘다니 취임

- [신년 사설] 붉은 말의 힘찬 기상·역동성으로 도전과 성취를

- 뉴욕한인회 김동민 고문 변호사 문영운… 1

- 뉴욕시민 기대수명 82.6세⋯팬데믹 이전 회복

- 변종 수퍼독감 ‘비상’ 사망자 3,100명 넘어

- 미 거주 한인 255만명… 전세계 최다

- 2025 체육대상에 태권도 이재국씨

- 온라인에 가짜 광고 ‘렌트 사기’ 기승

- 댄스동우회 아름다운동행, 더나눔하우스에 후원금 전달

- 김민선 백악관 역사위 자문위원 위촉 축하 행사

- 유명 성우 송도순 별세

- 뉴욕시 신임 교육감에 카마 사무엘스 학군장 내정

- 뉴욕한인교역자연합회 송년감사예배

- 미군에 쫓기는 베네수行 유조선 감싼 … 1

- [신년 휘호] 천상운집(天祥雲集) 백복병진(百福騈臻)

- 활동적 은퇴자 급증…한인시니어센터 “다 찼어요”

- CD 금리 하락, 주식은 불안… ‘원금 지키며 시장에 참여하는 방법’

- 나나, 강도 피해→역고소 사건에 입 열었다.. “말도 안 되는 상황”

- 대한항공, 새해 첫 고객맞이 행사

- 코란에 손 얹고… 뉴욕 첫 무슬림시장 취임 선서

- 국힘 “더 심한 사안 나오기 전 사퇴”…점점 세지는 李낙마 공세(

- “트럼프 리조트 마사지사들, 엡스타인에 방문 서비스”

- ‘우크라서 날아온 감사의 국기’

- 비트코인, 연 하락마감 3년만에 내림세로 돌아

- 연준 12월 금리인하… ‘만장일치 실패’

- [신년 축시] 새해 아침

- [조지 F. 윌 칼럼] AI 투자 붐이 걱정된다면?… 역사적 맥락을 보라

- [신년 휘호] 光明大道 (광명대도)

- 美스타트업서 가장 인기있는 창업자 학위는…석박사 아닌 ‘중퇴’

- LA 등 배치 주방위군 ‘불법’… 완… 1

- LA카운티 ‘원숭이두창’ 감염 발생

- 라우든 일대 3인조 구리선 절도단 체포…피해액 수백만불

- 트럼프, 가구 관세 인상 1년간 연기

- “美, 평택기지 비행대대 비활성화”…주한미군 감축 관련성 주목

- KCM, 세 아이 아빠 됐다…지난달 셋째 득남

- [김재천 칼럼] 2026년, 미·중 대타협은 가능할까

- 연말 샤핑 ‘역대 최고’ 사상 첫 1조달러 돌파

- [미리 보는 CES 2026 ] “올해 핵심 트렌드… AI·로봇·모빌리티·디지털 건강”

- 올해 월가서 역대 최대급 기업공개 예고

1/5지식톡

-

미 육군 사관학교 West Poin…

0

미 육군 사관학교 West Poin…

0https://youtu.be/SxD8cEhNV6Q연락처:wpkapca@gmail.comJohn Choi: 714-716-6414West Point 합격증을 받으셨나요?미 육군사관학교 West Point 학부모 모…

-

☝️해외에서도 가능한 한국어 선생님…

0

☝️해외에서도 가능한 한국어 선생님…

0이 영상 하나면 충분합니다!♥️상담신청문의♥️☝️ 문의 폭주로 '선착순 상담'만 진행합니다.☎️ : 02-6213-9094✨카카오톡ID : @GOODEDU77 (@골뱅이 꼭 붙여주셔야합니다…

-

테슬라 자동차 시트커버 장착

0

테슬라 자동차 시트커버 장착

0테슬라 시트커버, 사놓고 아직 못 씌우셨죠?장착이 생각보다 쉽지 않습니다.20년 경력 전문가에게 맡기세요 — 깔끔하고 딱 맞게 장착해드립니다!장착비용:앞좌석: $40뒷좌석: $60앞·뒷좌석 …

-

식당용 부탄가스

0

식당용 부탄가스

0식당용 부탄가스 홀세일 합니다 로스앤젤레스 다운타운 픽업 가능 안녕 하세요?강아지 & 고양이 모든 애완동물 / 반려동물 식품 & 모든 애완동물/반려동물 관련 제품들 전문적으로 홀세일/취급하는 회사 입니다 100% …

-

ACSL 국제 컴퓨터 과학 대회, …

0

ACSL 국제 컴퓨터 과학 대회, …

0웹사이트 : www.eduspot.co.kr 카카오톡 상담하기 : https://pf.kakao.com/_BEQWxb블로그 : https://blog.naver.com/eduspotmain안녕하세요, 에듀스팟입니다…

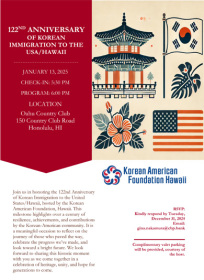

케이타운 1번가

오피니언

손영아 문화 칼럼니스트 / YASMA7 대표

손영아 문화 칼럼니스트 / YASMA7 대표 [손영아의 문화산책] ‘슈만의 연가’… 170년 전 멈춘 시간, 끝나지 않은 사랑

김재천 서강대 국제대학원 교수

김재천 서강대 국제대학원 교수 [김재천 칼럼] 2026년, 미·중 대타협은 가능할까

조지 F·윌 워싱턴포스트 칼럼니스트

조지 F·윌 워싱턴포스트 칼럼니스트 [조지 F. 윌 칼럼] AI 투자 붐이 걱정된다면?… 역사적 맥락을 보라

이희숙 시인·수필가

이희숙 시인·수필가 [금요단상] 차가운 길, 이불 한 장의 온기

한영일 / 서울경제 논설위원

한영일 / 서울경제 논설위원 [만화경] 33년만에 퇴역하는 장보고함

[왈가 왈부] 이혜훈 ‘정말 널 죽였으면’ 폭언, 장관직 수행 가능할까요

정숙희 논설위원

정숙희 논설위원샴페인, 마지막 날과 첫날을 위하여

조지 F·윌 워싱턴포스트 칼럼니스트

조지 F·윌 워싱턴포스트 칼럼니스트 [조지 F. 윌 칼럼] 저무는 2025년에 안도의 한숨

김동찬 시민참여센터 대표

김동찬 시민참여센터 대표 [미국은 지금] 책임 있는 자본 없으면 커뮤니티 미래도 없다

1/3지사별 뉴스

뉴욕시 첫 무슬림 시장 맘다니 취임

미국 최대도시이자 경제 수도로 꼽히는 뉴욕시의 첫 무슬림·남아시아계 시장이자 스스로를 민주사회주의자라고 부르는 조란 맘다니 신임 뉴욕시장이 새…

뉴욕시민 기대수명 82.6세⋯팬데믹 이전 회복

건국 250주년 워싱턴 모뉴먼트 라잇쇼

워싱턴 DC 내셔널 몰 중심에 위치한 워싱턴 모뉴먼트(Washington Monument)가 화려한 불빛으로 장식됐다. 지난 31일 새해 카운…

“소확행<작지만 확실한 행복> 즐겨요”

병오년 2026년 시작을 알리는 꽃가루

지난달 12월 31일 뉴욕 타임스퀘어 에서 열린 볼 드롭 행사에서 찬란한 볼이 새해를 알린 직후 2026년 1월 1일 0시를 기해 이날 메인 …

중부 캘리포니아 ‘한인 이민사’ 나왔다

오늘 하루 이 창 열지 않음 닫기

.png)

댓글 안에 당신의 성숙함도 담아 주세요.

'오늘의 한마디'는 기사에 대하여 자신의 생각을 말하고 남의 생각을 들으며 서로 다양한 의견을 나누는 공간입니다. 그러나 간혹 불건전한 내용을 올리시는 분들이 계셔서 건전한 인터넷문화 정착을 위해 아래와 같은 운영원칙을 적용합니다.

자체 모니터링을 통해 아래에 해당하는 내용이 포함된 댓글이 발견되면 예고없이 삭제 조치를 하겠습니다.

불건전한 댓글을 올리거나, 이름에 비속어 및 상대방의 불쾌감을 주는 단어를 사용, 유명인 또는 특정 일반인을 사칭하는 경우 이용에 대한 차단 제재를 받을 수 있습니다. 차단될 경우, 일주일간 댓글을 달수 없게 됩니다.

명예훼손, 개인정보 유출, 욕설 등 법률에 위반되는 댓글은 관계 법령에 의거 민형사상 처벌을 받을 수 있으니 이용에 주의를 부탁드립니다.

Close

x