GAZIPUR, Bangladesh - The eight-lane highway leading from the Bangladeshi capital, Dhaka, narrows repeatedly as it approaches this town about 48 kilometers north, eventually depositing cars onto a muddy, potholed lane bordered by mangroves and small shops.

But this is no mere rural enclave. It is the sort of place to which foreign manufacturers may increasingly turn, if the rising wage demands of factory workers in China prompt companies to seek new pools of cheap labor elsewhere.

Already, in factories behind steel gates and tall concrete walls, tens of thousands of workers, most of them women, spend their days stitching T-shirts, pants and sweaters for Wal- Mart, H, Zara and other Western retailers and brands.

One of the Bangladeshi companies here, the DBL Group, employs 9,000 people making T-shirts and other knitwear. Business has been so good that the company is finishing a new 10-story building with open floors the size of soccer fields, planted with row after row of sewing machines.

“Our family needed the money, so we came here,” said Maasuda Akthar, a 21-year-old sewing machine operator for DBL.

As costs have risen in China, long the world’s shop floor, it is slowly losing work to countries like Bangladesh, Vietnam and Cambodia.

Li & Fung, a Hong Kong company that handles sourcing and apparel manufacturing for companies like Wal-Mart and Liz Claiborne, reported that its production in Bangladesh jumped 20 percent last year, while China, its biggest supplier, slid 5 percent.

“Bangladesh is getting very competitive,” William Fung, Li & Fung’s group managing director, told analysts in March.

The flow of jobs started even before recent labor unrest in China led to big pay raises for many factory workers there - and before changes in Beijing’s currency policy that could also raise the costs of Chinese exports. Economists expect the migration of China’s low-paying jobs to accelerate.

Bangladesh has the lowest garment wages in the world, according to labor rights advocates. Ms. Akthar, who is relatively well paid by local standards, earns about $64 a month. That compares to minimum wages in China’s coastal industrial provinces ranging from $117 to $147 a month.

But China has a vast population of migrant workers, modern roads and power grids in industrial provinces. Most of Bangladesh suffers blackouts six to seven hours a day because it has not invested enough in power plants and natural gas fields - deficiencies that the government is working on but that will not be eliminated quickly.

The country has a literacy rate of only 55 percent ? compared with more than 92 percent in China. As a result, workers in this country are only one-fourth as productive as the Chinese in making shirts, jackets and other woven clothes, according to a report by the Center for Policy Dialogue, an independent research organization based in Dhaka.

Despite its handicaps, Bangladesh nearly doubled garment exports from 2004 to 2009. And the industry now employs about three million people, more than any other industrial segment in this largely agrarian country of 160 million. From June through November last year, garment exports accounted for more than 80 percent of the country’s total exports of $7.1 billion.

Among developing countries, Bangladesh is the third-biggest exporter of clothing after mainland China, which exported $120 billion in 2008, and Turkey, a distant No. 2, according to the World Trade Organization.

And as in China, workers in Bangladesh have started demanding higher pay. Garment workers are demanding a 200 percent increase in the minimum wage, to 5,000 taka (about $71) a month - which is how much workers with several years of experience now earn. The government, which plans to announce a new minimum wage soon, last increased it in 2006, to 1,662.50 taka (about $24). Since then, inflation has been as high as 9.9 percent a year.

“Most garment workers live in slum areas where one room costs 2,000 to 3,000 taka,” said Mushrefa Mishu, president of the Garment Workers’ Unity Forum, an association that claims to represent more than 60,000 members.

Factory owners here argue that a big increase in wages would make them uncompetitive against Vietnam and other big producers.

“If it’s 5,000 taka, I would close all my factories,” said Anisul Huq, a former head of the Bangladeshi garment industry’s trade group and a factory owner whose customers include H and Wal-Mart. “Even if it’s 3,000 taka, lots of factories will close within three or four months.”

By VIKAS BAJAJ

스마터리빙

more [ 건강]

[ 건강]이제 혈관 건강도 챙기자!

[현대해운]우리 눈에 보이지 않기 때문에 혈관 건강을 챙기는 것은 결코 쉽지 않은데요. 여러분은 혈관 건강을 유지하기 위해 어떤 노력을 하시나요?

[ 건강]

[ 건강]내 몸이 건강해지는 과일궁합

[ 라이프]

[ 라이프]벌레야 물럿거라! 천연 해충제 만들기

[ 건강]

[ 건강]혈압 낮추는데 좋은 식품

[현대해운]혈관 건강은 주로 노화가 진행되면서 지켜야 할 문제라고 인식되어 왔습니다. 최근 생활 패턴과 식생활의 변화로 혈관의 노화 진행이 빨라지고

사람·사람들

more

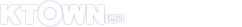

김응화 단장, 아쿠아리움 퍼시픽 ‘헤리티지 어워드’

김응화무용단의 김응화 단장이 롱비치의 아쿠아리움 오브 더 퍼시픽이 수여하는 2025년 ‘헤리티지 어워드’의 영예를 안았다. 올해 처음 개최된 …

이정임 무용원, 팬아시아 전통예술 경연대회

남가주 최대 규모의 아시아 전통 예술 경연대회인 팬아시아 댄스 앤 드럼 대회에서 이정임무용원의 청소년 단원들이 경연에 참가해서 전체 대상 등 …

유희자 국악무용연구소, 팬아시아 전통예술대회

지난 15일 샌개브리얼 셰라톤 호텔에서 열린 남가주 최대 규모의 전통 무용대회인 팬아시아 댄스 앤 드럼 대회에서 유희자 국악무용연구소(원장 유…

송년행사 안내해드립니다

다사다난했던 2025년이 이제 종착점을 향해 달려가고 있습니다. 한 해를 잘 마무리하고 2026년 새해를 힘차게 맞기 위한 다짐을 하는 송년 …

‘군중’ 시리즈 이상원 작가 첫 LA전시회

아케디아 소재 홈갤러리인 ‘알트프로젝트’(대표 김진형)가 오는 29일(토)부터 한국 블루칩 작가 이상원이 참여하는 전시 ‘인 드리프트(In D…

많이 본 기사

- 트럼프, ‘상극’ 맘다니에 “철학 다르나 ‘강한 뉴욕’ 목표 같아”

- “조지아 구금 근로자 약 50명, 미국 재입국해 현장 복귀”

- 화물기 폭발 사고 순간 공개…이륙하자마자 엔진 떨어져나가

- ‘우크라 종전’ 속도내는 트럼프 “합의 시한, 27일이 적절”

- [LA 오토쇼 특집] “자동차 시장 격동”… 전기·하이브리드 출시 ‘경쟁’

- X·그록·클라우드플레어 등 한때 접속장애…현재는 복구

- 1,600만불 메디케어 사기 일당 ‘… 2

- 美, 재외공관에 동맹국의 ‘대규모 이민’ 문제점 보고 지시

- 남가주에 또 폭풍우 최대 2인치 비 예보

- 공항 신원확인 강화… ‘리얼 ID’ 없으면 18달러 내야

- 매일 10분만 바꿔도… 당뇨 예방 6대 생활수칙

- 트럼프 2,000달러 관세 배당 없던일로?

- [오피셜] 손흥민-메시, 약 8만 관중 앞 맞대결 확정... 내년 MLS 개막전 격돌

- [LA Auto Show Special] “The Heyday of Hybrids and the Leveling-Up of Safety Technology”

- 황동혁 감독 ‘전폭 지원’ 속… ‘오징어 게임: 아메리카’, 내년 2월 촬영 돌입 [★할리우드]

- 남아공 대통령 “美, G20 보이콧 번복” 주장 해프닝으로 끝나

- 유승준, 국내 음반 참여…저스디스 신곡 ‘홈 홈’ 피처링

- ‘유격수가 얼마나 귀한데… ‘ MLB닷컴, 김하성 ‘FA 3티어-1년 계약 가능성’ 전망

- 뉴욕연은 총재 “금리 추가조정 여지 남아”…12월 인하 기대 급등

- ‘모범택시3’ 첫화부터 액션 폭발..이제훈, 복면 쓰고 후쿠오카 인신매매판 급습

- 다카이치 “중일관계 방향성 변함없어”…中 “발언 철회해야”

- 박나래, 연하男에 다 퍼주는 연애사 고백..”평생 밀당해 본 적 없어”[나혼산]

- 리센느, 미니 3집 ‘lip bomb’, 선물처럼 찾아온 콘셉트 포토 BALM 버전 공개

- 수사외압 마지막 퍼즐 ‘임성근 구명로비’ 의혹 끝내 미제로

- 저승까지 추적… ‘신정동 연쇄살인범’ 20년 만에 찾았다

- 李대통령, 이집트 공식방문 끝내고 출국…G20 열리는 남아공으로

- UC 등록금 치솟는다 “매년 최고 5% 인상”

- 10월 소비자물가 발표 취소… “셧다운으로 설문조사 못해”

- “히터도 못켜요”… 올 겨울 난방비 ‘역대급’

- 특검, 김건희-건진법사 연결고리 ‘도이치 주포’ 구속영장 청구

- [화제] ‘온통 황금’… 변기 하나에 1,200만불

- 이민단속요원 막무가내 “문 열어라”

- 한인 추정 40대 여성 자금세탁 121개월형

- 이민법원 적체에… 한인들‘신분 위기’

- 연말시즌 온라인 샤핑 노린 사기 ‘기승’

- 나란히 선 미 대통령·부통령 부인

- 론 김 뉴욕주하원의원, 플러싱 YMCA에 건축지원금 300만불 전달

- [알립니다]‘온정의 슬리핑백’ 보내기 운동

- UC 등록금 치솟는다 “매년 최고 5% 인상”

- “안전·깨끗한 한인타운 만들기” 함께 나선다

- 체니 전 부통령 장례식… 부시·바이든 참석, 트럼프는 불참

- ‘2025 뉴욕 미슐랭 가이드’에 한인 레스토랑 12곳 선정

- 최소의 노력으로 최대 효과를 노리는 401(k)

- “최첨단 신차들 한 눈에”… 2025 LA 오토쇼 개막

- “늦기전 시민권 신청 서두르세요”

- LA 교통정체 40년째 전국 ‘최악’

- “행복하게 살았답니다”..신민아♥김우빈, 누적 기부액 51억 커플의 ‘해피엔딩’

- “해외서 한글로 쓰는 마음”… 재외동포문학상 시상식

- ‘트럼프 정적’ 코미 기소 “절차 위반”

- 2025년 교사 ‘사은의 밤’ 개최

1/5지식톡

-

테슬라 자동차 시트커버 장착

0

테슬라 자동차 시트커버 장착

0테슬라 시트커버, 사놓고 아직 못 씌우셨죠?장착이 생각보다 쉽지 않습니다.20년 경력 전문가에게 맡기세요 — 깔끔하고 딱 맞게 장착해드립니다!장착비용:앞좌석: $40뒷좌석: $60앞·뒷좌석 …

-

식당용 부탄가스

0

식당용 부탄가스

0식당용 부탄가스 홀세일 합니다 로스앤젤레스 다운타운 픽업 가능 안녕 하세요?강아지 & 고양이 모든 애완동물 / 반려동물 식품 & 모든 애완동물/반려동물 관련 제품들 전문적으로 홀세일/취급하는 회사 입니다 100% …

-

ACSL 국제 컴퓨터 과학 대회, …

0

ACSL 국제 컴퓨터 과학 대회, …

0웹사이트 : www.eduspot.co.kr 카카오톡 상담하기 : https://pf.kakao.com/_BEQWxb블로그 : https://blog.naver.com/eduspotmain안녕하세요, 에듀스팟입니다…

-

바디프렌드 안마의자 창고 리퍼브 세…

0

바디프렌드 안마의자 창고 리퍼브 세…

0거의 새제품급 리퍼브 안마의자 대방출 한다고 합니다!8월 23일(토)…24일(일) 단 이틀!특가 판매가Famille: $500 ~ $1,000Falcon: $1,500 ~ $2,500픽업 & 배송직접 픽업 가능LA…

-

바디프렌드 안마의자 창고 리퍼브 세…

0

바디프렌드 안마의자 창고 리퍼브 세…

0거의 새제품급 리퍼브 안마의자 대방출 한다고 합니다!8월 23일(토)…24일(일) 단 이틀!특가 판매가Famille: $500 ~ $1,000Falcon: $1,500 ~ $2,500픽업 & 배송직접 픽업 가능LA…

케이타운 1번가

오피니언

조지 F·윌 워싱턴포스트 칼럼니스트

조지 F·윌 워싱턴포스트 칼럼니스트 [조지 F. 윌 칼럼] 세계를 가장 크게 바꾼 사건, 미국 혁명전쟁

이희숙 시인·수필가

이희숙 시인·수필가 [금요단상] 낙엽 위에 남겨진 향

김정곤 / 서울경제 논설위원

김정곤 / 서울경제 논설위원[만화경] ‘중동판 꽌시’ 와스타

[왈가 왈부] ‘패트 충돌’ 선고에 여야 “정치 판결” “자성 촉구” 아전인수?

수잔 최 한미가정상담소 이사장 가정법 전문 변호사

수잔 최 한미가정상담소 이사장 가정법 전문 변호사 [수잔 최 변호사의 LIFE &] 서울 가을 자락에서 만난 쉼터

강민수 을지대 첨단학부 교수 한국인공지능학회장

강민수 을지대 첨단학부 교수 한국인공지능학회장 [기고] 디지털 주권의 토대, 소버린 클라우드

1/3지사별 뉴스

론 김 뉴욕주하원의원, 플러싱 YMCA에 건축지원금 300만불 전달

론 김 뉴욕주하원의원이‘플러싱 커먼스’(Flushing Commons)에 새롭게 들어설 예정인 플러싱 YMCA에‘건축지원금’(Capital F…

이민법원 적체에… 한인들‘신분 위기’

“함께 만들어 가는 평화의 약속”

“오늘 출범식은 단순한 시작이 아니라 한인사회와 함께 만들어가는 평화와 희망의 약속입니다. 한반도의 평화는 거대한 정치적 언어가 아닌 우리 같…

VA 34%·MD 30%만 모기지 ‘0’

UC 등록금 치솟는다 “매년 최고 5% 인상”

UC 이사회가 매년 최대 5%까지 신입생들의 등록금을 인상할 수 있는 ‘등록금 안정화 프로그램’을 통과시켜 향후 UC 학생들과 학부모들의 학비…

[알립니다]‘온정의 슬리핑백’ 보내기 운동

오늘 하루 이 창 열지 않음 닫기

.png)

댓글 안에 당신의 성숙함도 담아 주세요.

'오늘의 한마디'는 기사에 대하여 자신의 생각을 말하고 남의 생각을 들으며 서로 다양한 의견을 나누는 공간입니다. 그러나 간혹 불건전한 내용을 올리시는 분들이 계셔서 건전한 인터넷문화 정착을 위해 아래와 같은 운영원칙을 적용합니다.

자체 모니터링을 통해 아래에 해당하는 내용이 포함된 댓글이 발견되면 예고없이 삭제 조치를 하겠습니다.

불건전한 댓글을 올리거나, 이름에 비속어 및 상대방의 불쾌감을 주는 단어를 사용, 유명인 또는 특정 일반인을 사칭하는 경우 이용에 대한 차단 제재를 받을 수 있습니다. 차단될 경우, 일주일간 댓글을 달수 없게 됩니다.

명예훼손, 개인정보 유출, 욕설 등 법률에 위반되는 댓글은 관계 법령에 의거 민형사상 처벌을 받을 수 있으니 이용에 주의를 부탁드립니다.

Close

x