Traditional Lacquer Ware Craft in Need of Advancement

Staff Reporter

SEOUL?orean lacquer ware tradition traces its roots back to the pre-Three Kingdom era. ?acquer ware artifacts have ben unearthed from many ancient tombs, said Kim Cha-bong, 62, who has devoted 46 years of his life to lacquer craftsmanship.

The Korean craftsmanship tradition allows only the naturally obtained color red or transparent lacquer for painting wooden structures.

The color pigments which are mixed with oil derived from pine sap before being painted on wooded wares are simply lacquer powder dyed naturally in all colors. The transparent lacquer is obtained by stirring purified lacquer for quite a long time either manually or by using a machine. The lacquer coating has to be as smooth as possible. ?f I find any unevenness in the lacquer coating, then I polish the surface and apply another coating, until I achieve a blemish-free product, Kim, who learned his craft in Tongyong, Kyongsang-namdo said.

He acknowledged that some people have allergic reactions to lacquer as they suffer itchiness and skin rashes when they come in direct contact with raw lacquer or wooden wares coated with it.

However, lacquer wares are hotly sought after by many people despite their steep price tags.

?acquer naturally possesses a special anti-cancer substance in it. It kills germs upon direct contact and is good for consumption as it prevents various illnesses by clearing the stomach and blood stream. Lacquer coating also prevents wood from rotting. Kim said.

Koreans have long known these positive and healthy qualities of lacquer coated wooden wares before modern science discovered them. The lacquer is obtained from the lacquer tree.

Kim said that the best time to collect lacquer is autumn when it has the appropriate amount of moisture.

?orean lacquer is harder when dried and more penetrating when coated on wooden wares than its Chinese or Japanese counterparts. Also, Korean lacquer spreads over double the surface area using the same amount than Japanese or Chinese lacquer, Kim said.

The lacquer is squeezed through filters made of ramie or silk gauze, although nylon gauze is preferred nowadays. Then the lacquer is further purified through squeezing it through a cotton layer placed between sheets of special paper. At the end of the grueling process, the color of the lacquer changes from lavender to milk white.

At his home workshop in Kure, Kyonggi-do, Kim has been endeavoring to advance lacquer ware craft so that implements can be made for the daily use. ? make virutally every tool used in dining with lacquer coated wooden wares such as rice bowls, soup bowls, forks and knives, chop sticks and spoons, coffee cups and saucers, dining tables, liquor bottles, glasses and flower bases just to name a few, he said.

Humidity and temperature has to be just right for lacquer coating to dry properly.

Kim said, ? place my freshly lacquer coated ware to dry in a special room for four hours where the humidity is set to 60-65 percent and temperature to 25-30 degrees Celsius. Then I take them out and dry them in the room for one whole day, Only then, the lacquer hardens completely and properly.

Interestingly, the brushes he uses to paint his wooden wares with lacquer are made out of human hair as he said, ?uman hair is the most resilient and of the finest quality for lacquer painting.

To place orders for his lacquer wares, call him at his workshop (0346-572-0520) or at his office (02-436-5440-l).

스마터리빙

more [ 건강]

[ 건강]이제 혈관 건강도 챙기자!

[현대해운]우리 눈에 보이지 않기 때문에 혈관 건강을 챙기는 것은 결코 쉽지 않은데요. 여러분은 혈관 건강을 유지하기 위해 어떤 노력을 하시나요?

[ 건강]

[ 건강]내 몸이 건강해지는 과일궁합

[ 라이프]

[ 라이프]벌레야 물럿거라! 천연 해충제 만들기

[ 건강]

[ 건강]혈압 낮추는데 좋은 식품

[현대해운]혈관 건강은 주로 노화가 진행되면서 지켜야 할 문제라고 인식되어 왔습니다. 최근 생활 패턴과 식생활의 변화로 혈관의 노화 진행이 빨라지고

사람·사람들

more많이 본 기사

- “전문직비자(H-1B) 수수료 1인 … 1

- 미국 의회서 한국인 전문직 취업비자 법안 추가 발의

- 하원서 암살된 커크 추모 결의안 통과…민주 58명 반대표

- ‘청년 우파 아이콘’ 찰리 커크 아내… 1

- 미중정상 통화 논의하자…틱톡 모회사 “중국법 따라 작업 추진”

- “李대통령 피습, 법적으론 테러 어려… 1

- 내란특검, 평양 무인기 의혹 ‘정점’ 尹에 24일 소환 통보

- 마이런 연준 이사 “관세, 인플레이션 유발하지 않아”

- ‘호주 전용 전문직 취업비자’ 대상에 한국인 포함 법안 재추진

- 이재명 대통령, 22∼26일 뉴욕 방… 1

- 뉴욕시 STAR 수혜주택, 밀폐 쓰레기통 구입비 보상

- 상원, 트럼프 참석 유엔총회 직전 왈츠 유엔대사 인준

- “소에 얼룩무늬 칠해 파리 쫓는다”…… 1

- 트럼프-시진핑, 경주APEC서 대좌…… 1

- 전문직 취업비자 수수료 ‘10만 달러’로 올린다

- 하마스에 584일 억류됐던 美이중국적자 “내달 이스라엘군 복귀”

- 하원 통과한 임시예산안 상원서 부결…셧다운 우려 부상

- 전국 모기지 금리… 1년 만에 최저치

- 유승준 비자소송 어디까지, 3번 패소… 1

- 고삐 풀린 소고기 가격… 소비자·식당들 ‘멘붕’

- 중학생들 등굣길 학교 정문서 불체자 추격·체포 ‘경악’

- 해외관광객 미국 기피… 관광 업계 ‘울상’

- 뉴욕증시, 금리인하 훈풍에 3대지수 최고치 마감…다우 0.4%↑

- 6가에 ‘차 없는 거리’ 시범설치 확… 2

- ‘졸업의 기쁨도 잠시’… 주 학자금 연체 대출자 급증

- 택시기사 그만두고 본업 컴백? 정가은 “아침부터 섭외 전화.. “알고 보니

- 맨발걷기 월례모임

- 이민법원 한인 판사까지 쫓겨났다 1

- 커크 피살후 트럼프 정부 ‘좌파 척결’ 속도…신매카시즘 그림자

- ‘미국 입국거부’ 아바스 팔 수장, 유엔총회서 화상으로 연설

- ‘대장동’ 또 말바꾼 남욱 진술 널뛰기…이번엔 “검찰 말대로”

- “발을 따뜻하게 하면 수면제만큼 잠드는 데 효과적”

- 테슬라, 오토파일럿 사망소송 합의

- “美정부, 이스라엘에 57억달러 규모 공격용 무기 판매 계획”[WSJ]

- [주말 뭐 볼까 OTT] “입양한 7세 여아, 알고보니 성인”…진실·다면성·편견을 묻다

- “머스크의 xAI, 기업가치 2천억달러 평가로 추가 자금 조달”

- ‘이우환 그림 수수’ 김건희 오빠 9시간 특검조사…증거은닉 의혹

- ‘美에 항전태세’ 베네수엘라, 일반주민 상대 군사교육 개시

- 김완선·송가인도 줄줄이..강동원 측 … 1

- [전문가 에세이] 뇌 세포를 사망시키는 8가지 습관

- 메타, 고해상도의 첫 스마트 안경 출시

- 22기 SF 평통 신청 마감, 정원 미달**추후 추가모집

- 코윈 퍼시픽 LA 5대 회장단 이취임식

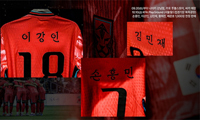

- ‘몰아치기 능력자’ 손흥민, 첫 홈경기 득점+3경기 연속골 노린다

- 미등록 기획사 의혹…경찰, 강동원·씨엘 수사 착수

- 캔맥주·콜라 가격 계속 오른다

- “브로드웨이의 명작, 오페라의 품격으로 재탄생”

- 주차장 성폭행 ‘나는 솔로’ 30대男 집행유예.. “피해자 합의, 처벌 NO”

- 가수 명의 테슬라 트렁크서 10대 소녀 시신 발견 ‘발칵’

- [한국춘추] 케데헌 속 호작도, 그리고 민화의 세계

1/5지식톡

-

ACSL 국제 컴퓨터 과학 대회, …

0

ACSL 국제 컴퓨터 과학 대회, …

0웹사이트 : www.eduspot.co.kr 카카오톡 상담하기 : https://pf.kakao.com/_BEQWxb블로그 : https://blog.naver.com/eduspotmain안녕하세요, 에듀스팟입니다…

-

바디프렌드 안마의자 창고 리퍼브 세…

0

바디프렌드 안마의자 창고 리퍼브 세…

0거의 새제품급 리퍼브 안마의자 대방출 한다고 합니다!8월 23일(토)…24일(일) 단 이틀!특가 판매가Famille: $500 ~ $1,000Falcon: $1,500 ~ $2,500픽업 & 배송직접 픽업 가능LA…

-

바디프렌드 안마의자 창고 리퍼브 세…

0

바디프렌드 안마의자 창고 리퍼브 세…

0거의 새제품급 리퍼브 안마의자 대방출 한다고 합니다!8월 23일(토)…24일(일) 단 이틀!특가 판매가Famille: $500 ~ $1,000Falcon: $1,500 ~ $2,500픽업 & 배송직접 픽업 가능LA…

-

미주 한인 세무사 전국 대회- 20…

0

미주 한인 세무사 전국 대회- 20…

02025 전미한인세무사협회 컨퍼런스2025 THEME: Navigating New Frontiers(국제조세, 부동산투자, 블루오션 시장이라는 키워드를 아우르면서, 세무사들이 기존의 영역을 넘어 새로운 기회를 탐색…

-

애틀랜타/조지아로 이사 예정이신가요…

0

애틀랜타/조지아로 이사 예정이신가요…

0

케이타운 1번가

오피니언

6가 ‘차 없는 거리’, 타운 발전 계기로

뿌리교육의 최전선, 한국어 교육의 중요성

김미선 서북미문인협회 회장, 시인

김미선 서북미문인협회 회장, 시인 [한국춘추] 케데헌 속 호작도, 그리고 민화의 세계

제임스 조 풀러튼 교육위원

제임스 조 풀러튼 교육위원 [기고] 현대·LG 공장 이민 단속, 한인사회는 어떻게 대처해야 하는가?

이희숙 시인·수필가

이희숙 시인·수필가 [금요단상] 무대는 그들로 완성된다

신상철 / 고려대 고고미술사학과 교수

신상철 / 고려대 고고미술사학과 교수 [미술 다시보기] 고요하고 풍요로운 정물

홍병문 / 서울경제 논설위원

홍병문 / 서울경제 논설위원[만화경] 코닥 몰락과 닮은 포토샵 위기

한 영 재미수필가협회 회장

한 영 재미수필가협회 회장 [한영의 독서칼럼] 눈먼 자들의 도시

김응화 무용연구소 원장

김응화 무용연구소 원장 [기고] 변화되는 아이들, 인공지능 시대의 예술 교육

1/3지사별 뉴스

‘호주 전용 전문직 취업비자’ 대상에 한국인 포함 법안 재추진

E-4에 E-3 추가 투트랙 진행이민당국의 조지아주 현대 전기차 배터리 공장 단속 사태에 따른 후폭풍이 거세게 일고 있는 가운데 호주 전용 전…

전문직 취업비자 수수료 ‘10만 달러’로 올린다

VA 사전투표 시작…11월 1일까지

오는 11월 4일 버지니아 선거를 앞두고 오늘(19일)부터 11월 1일까지 사전투표(Early Voting)가 실시된다. 사전투표는 미리 투표…

중학생들 등굣길 학교 정문서 불체자 추격·체포 ‘경악’

“전문직비자(H-1B) 수수료 1인 年 10만 달러” 한미비자협상 영향 주목

도널드 트럼프 행정부가 ‘전문직 비자’로 불리는 H-1B 비자 수수료를 1인당 연간 10만 달러(약 1억4천만원)로 대폭 증액하기로 했다.트럼…

22기 SF 평통 신청 마감, 정원 미달**추후 추가모집

오늘 하루 이 창 열지 않음 닫기

.png)

댓글 안에 당신의 성숙함도 담아 주세요.

'오늘의 한마디'는 기사에 대하여 자신의 생각을 말하고 남의 생각을 들으며 서로 다양한 의견을 나누는 공간입니다. 그러나 간혹 불건전한 내용을 올리시는 분들이 계셔서 건전한 인터넷문화 정착을 위해 아래와 같은 운영원칙을 적용합니다.

자체 모니터링을 통해 아래에 해당하는 내용이 포함된 댓글이 발견되면 예고없이 삭제 조치를 하겠습니다.

불건전한 댓글을 올리거나, 이름에 비속어 및 상대방의 불쾌감을 주는 단어를 사용, 유명인 또는 특정 일반인을 사칭하는 경우 이용에 대한 차단 제재를 받을 수 있습니다. 차단될 경우, 일주일간 댓글을 달수 없게 됩니다.

명예훼손, 개인정보 유출, 욕설 등 법률에 위반되는 댓글은 관계 법령에 의거 민형사상 처벌을 받을 수 있으니 이용에 주의를 부탁드립니다.

Close

x